Circle Wrench -

I work as a machinist and as a machinist we have a few different ways to hold our cutting tools into our machines. Shrink fit, set screws, collets, the list goes on. What I am talking about today is a type of nut which is used with a collet. If you are the vast majority of the population and have no idea what I am talking about, let me explain.

What is a collet? #

Imagine a collet as your fingers. If you have a pencil resting in your fingers, it will slip out. Using your fingers, you can clamp down on the pencil and prevent it from sliding. This is similar to how a collet works. Unlike fingers, a collet is sadly pretty useless on its own without a collet nut. This no problem for you because I have another analogy! The collet nut can be imagined as a rubber band. You wrap it around your fingers tigtly to help squeeze down on the pencil.

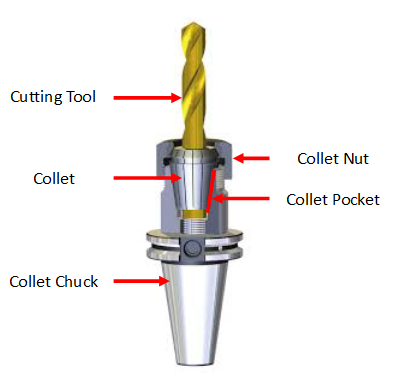

When you look at the diagram to the right, you can see the collet nut at the top surrounding the collet. It has threads on the inside which let you tighten it down to the collet chuck. This allows the nut to press the collet down into the pocket, squeezing it together, clamping on the tool. You can see this on the highlighted red edge. Think of wrapping the rubber band around your fingers multiple times here. The more you loop the rubber band, the tighter the grip you have on the pencil. The more you tighten the collet nut, the tighter the grip the collet has on the tool.

When you look at the diagram to the right, you can see the collet nut at the top surrounding the collet. It has threads on the inside which let you tighten it down to the collet chuck. This allows the nut to press the collet down into the pocket, squeezing it together, clamping on the tool. You can see this on the highlighted red edge. Think of wrapping the rubber band around your fingers multiple times here. The more you loop the rubber band, the tighter the grip you have on the pencil. The more you tighten the collet nut, the tighter the grip the collet has on the tool.

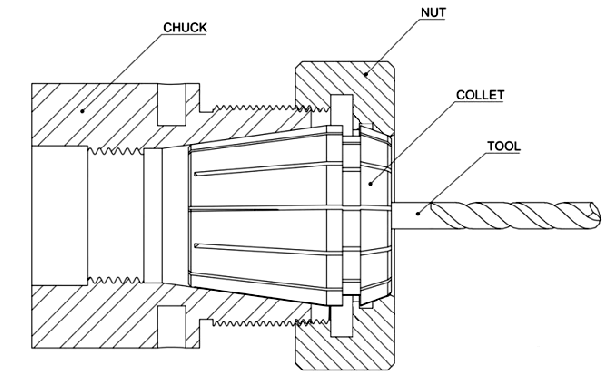

Below is another diagram with a little more detail to give you another look.

What does any of this have to do with a circle wrench? #

Collets range in many different sizes. The ER11 collet is what I am talking about today. It is small, perhaps the same diameter as a United States 1 cent coin. The advantage of smaller collets is that they are smaller in the machine. You can get in to smaller places with them. Most of the time, the collet nut is the largest part of the tool holder since it has to wrap around the collet. If you can shrink the collet nut down to the absolute smallest size, that can be extremely handy in the world of 5 AXIS machining.

That's where this guy comes into play. The circle nut. At first glance, you might think I'm joking. Let me assure you that this is a real tool I use. It mostly comes in handy when I need to tilt a part 90 degrees to put a hole in the side without crashing into the jaws. How do you even tighten a cirle nut down? If it's too loose, the tool will just spin in the collet! Well that's where one of the weirdest tools I've ever seen comes in..

That's where this guy comes into play. The circle nut. At first glance, you might think I'm joking. Let me assure you that this is a real tool I use. It mostly comes in handy when I need to tilt a part 90 degrees to put a hole in the side without crashing into the jaws. How do you even tighten a cirle nut down? If it's too loose, the tool will just spin in the collet! Well that's where one of the weirdest tools I've ever seen comes in..

The Circle Wrench itself #

This is the circle collet wrench! As you can see in the picture below, it merely has a circle opening designed to be the used specifically with the circle collet nut. I have absolutely no clue how this thing works, nor I cant find anything about it online. I only have it because it came with the collet nut. Boy does this thing work. It can somehow grip the circle nut so insanely well that I have no worries using about it coming loose.

There is a switch to flip it from lock and unlock (tighten and loosen). It flips something inside but I don't know what. The mechanism just rotates a little and BAM now it works in whichever way you flipped it. There are some pins along the inside and I think these are what grip the nut. It can seriously tighten down the circle nut just like any other wrench I have. If anyone has a clue as to how this work, please leave a comment!

There is a switch to flip it from lock and unlock (tighten and loosen). It flips something inside but I don't know what. The mechanism just rotates a little and BAM now it works in whichever way you flipped it. There are some pins along the inside and I think these are what grip the nut. It can seriously tighten down the circle nut just like any other wrench I have. If anyone has a clue as to how this work, please leave a comment!

Using the Circle Wrench #

The only downside to this tool is that after using it for the first time, I noticed it marred up the collet nut a little. Both are still 100% functional, but the apperance has taken a blow. It's also a little annoying to use because theres nothing from stopping you from continuing down the toolholder and attempting to tighten the shaft. The toolholder shaft is the same diameter as the cricle nut, so if the wrench overlaps the two parts just a little, you won't be able to to tighten it!

Touching off and using the tool! #

The left video is how I measure tool lengths in the machine. It's all wireless. I might do an entire writeup about the WIPS system in this machine. Might. I needed the reach and clearance for drilling 16 1/16'' holes in the part on the right! It's hard to see amidst all the coolant, but its an aluminum thing. I don't know what it does (as how it is with 90% of what I make).

Theres a lot of cool little tools I get to use as a machinist. I like tools and I like typing, so don't be surprised if you see an entry on some of my other tools in the future. Measuring tools are the ones I find to be the most plasma. Micrometers, calipers, they're all so interesting how they can measure so precisely.

Thanks for reading all this. See ya next time!